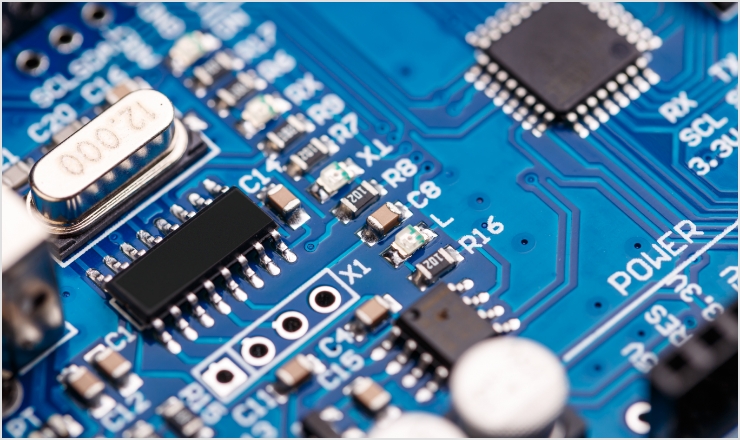

ProductsHigh Heat-Resistant Technology

Probes Engineered for Stability Under Extreme Conditions

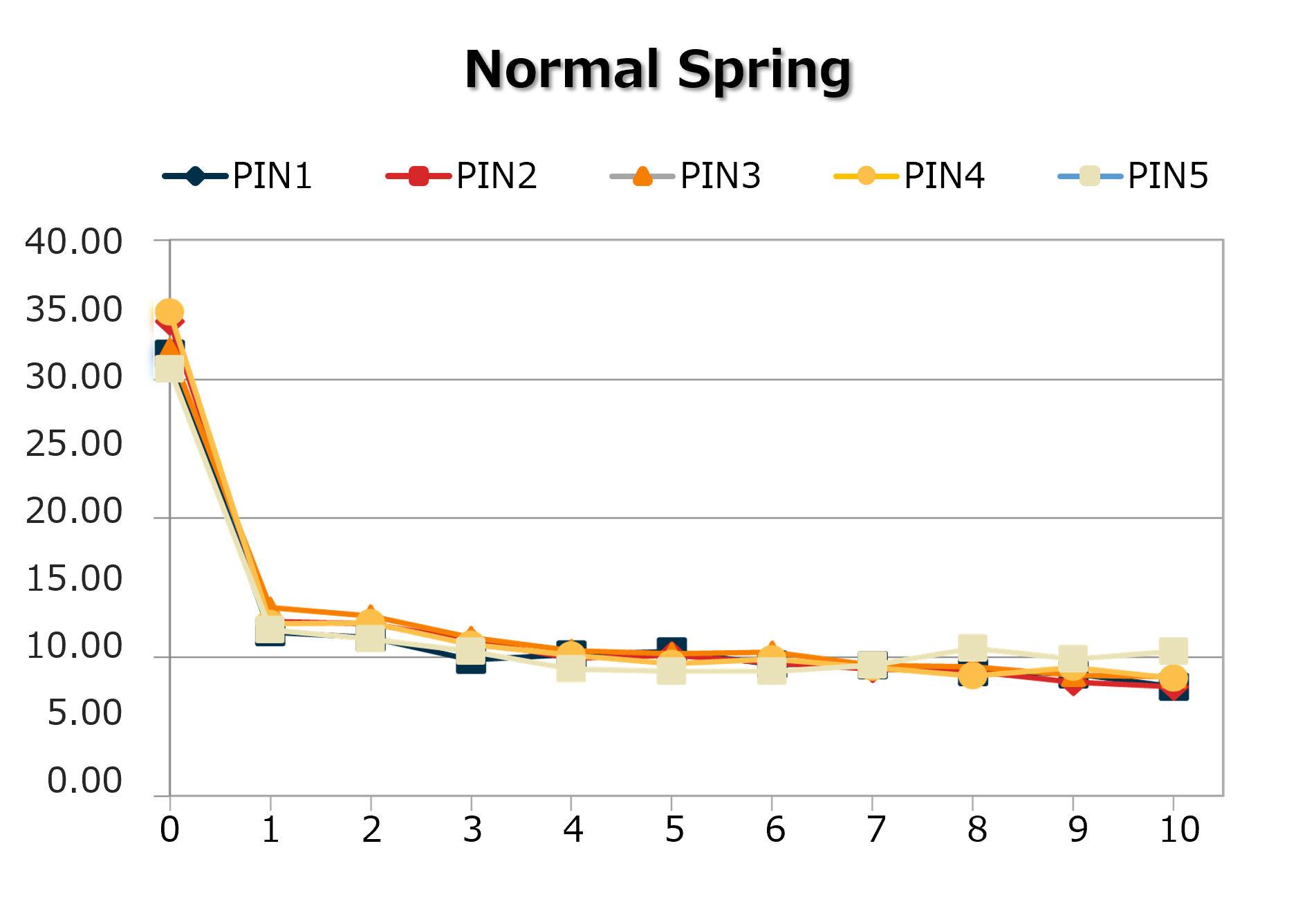

In conventional contact probes, piano wire (SWP) is often used as the spring material. While this is sufficient for room temperature applications, its performance degrades at higher temperatures. When exposed to elevated heat, the spring force decreases, making it difficult to maintain the required contact pressure for reliable measurements.

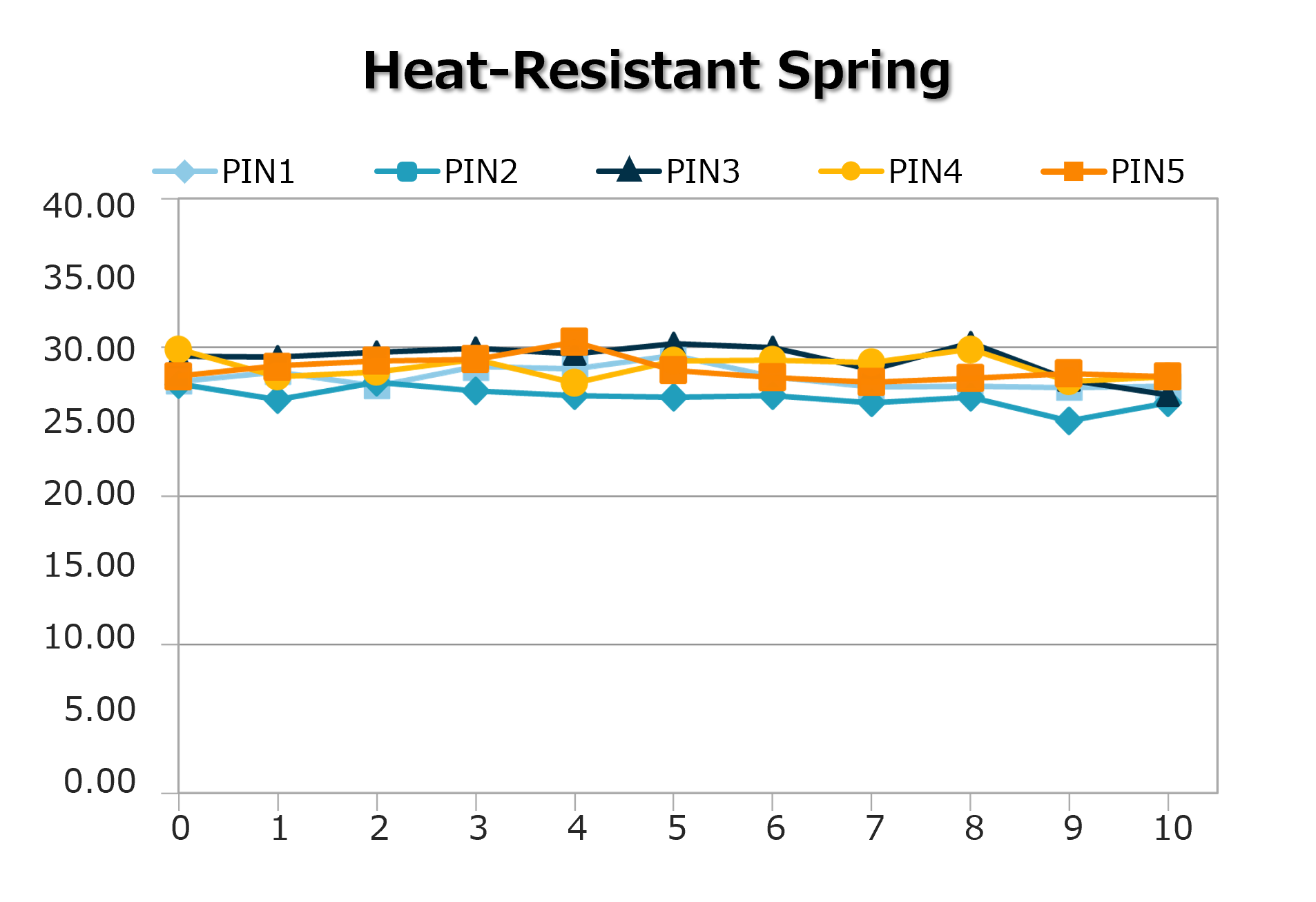

To address this, stainless steel (SUS) springs have traditionally been used. However, even SUS struggles to maintain performance around 200 °C. Seiken offers a next-generation solution by combining heat-resistant components, including springs c that handle up to 300°C, to significantly improve probe durability and maintain performance in harsh environments.

Key Features & Advantages

01 Reliable performance under high-temperature conditions

Our probes feature 300°C heat-resistant springs, ensuring reliable contact force and consistent performance even under extreme heat. Ideal for applications that demand long-term stability in elevated temperature environments.

02 Probe designed to minimize heat buildup

When high current passes through the probe, accumulation of heat can occur. Seiken’s heat-resistant design handles this challenge effectively, maintaining stable resistance values and minimizing measurement fluctuations—even during temperature spikes caused by current load.

03 Custom solutions for special requirements

We also offer custom probe designs to meet unique demands such as non-magnetic materials or other special conditions. Whatever your testing environment, Seiken can tailor a solution to meet your needs.

Application Examples

Explore more

- Power devices

- High-temperature IC evaluation systems

- Burn-in testing, etc.