~From SIP to Ceramic Packages – Practical Guide to Legacy IC Packaging~

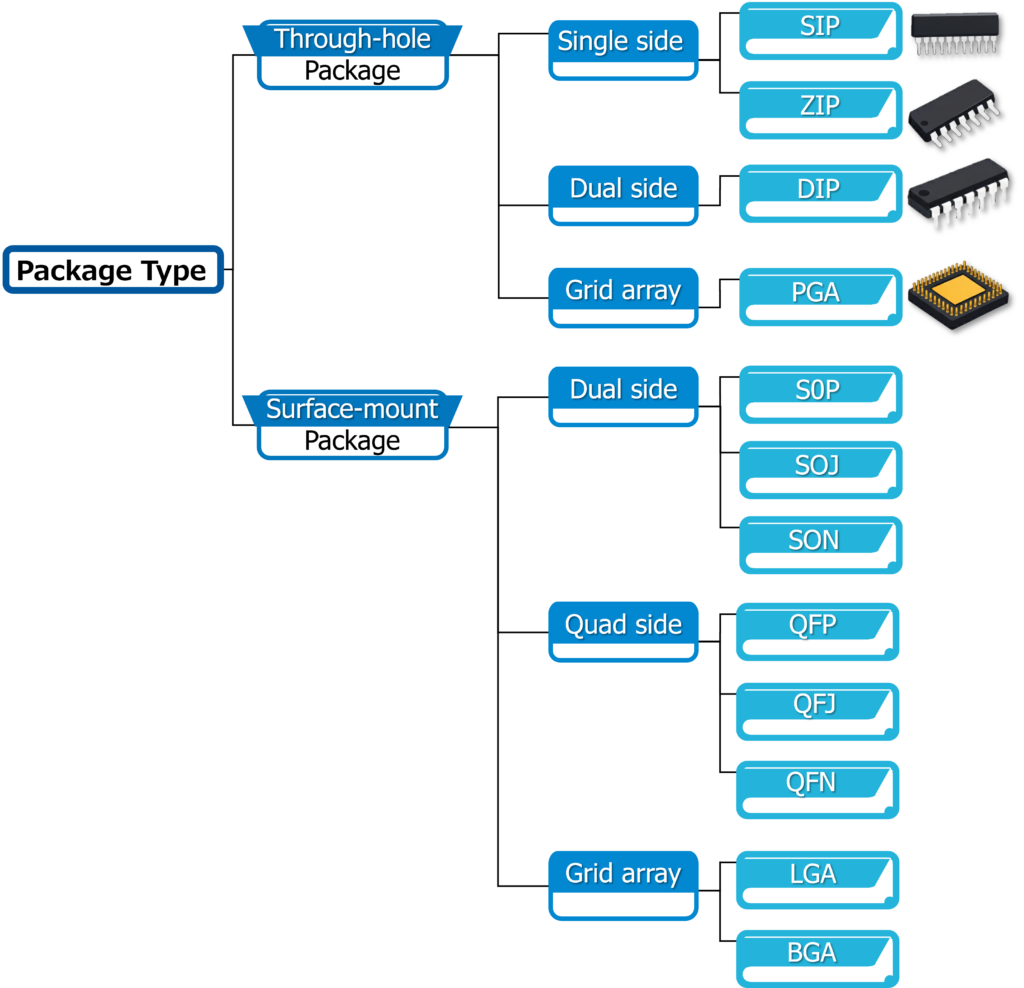

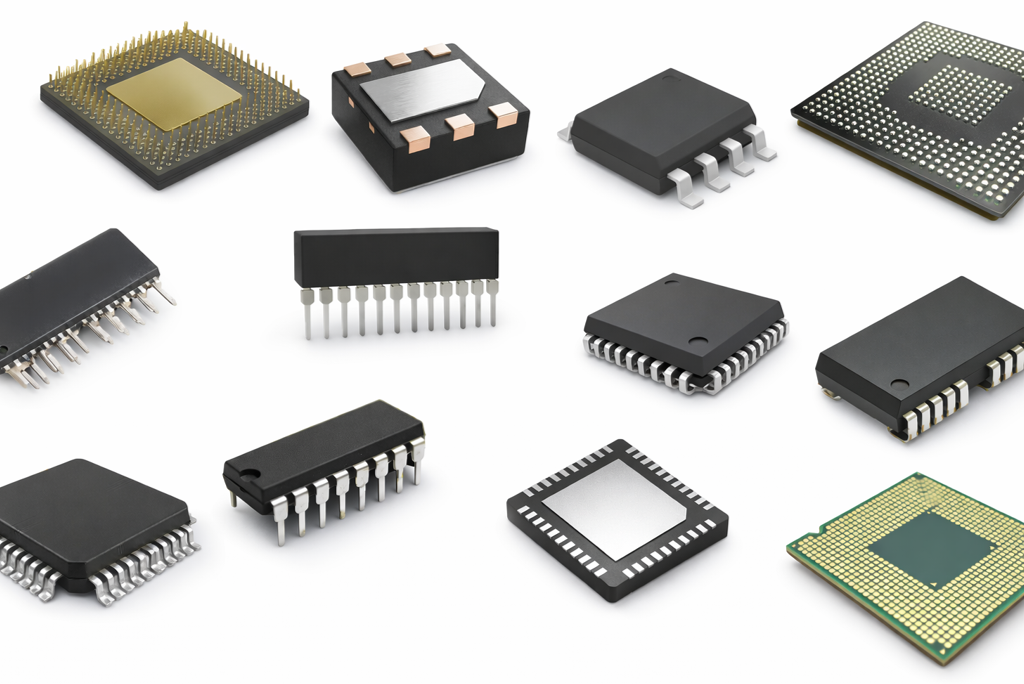

DIP・PGA are classic examples of through-hole semiconductor packages, a packaging technology that has supported the evolution of electronic devices for decades. Semiconductor packages are generally classified into through-hole mounting and surface-mount mounting, with through-hole technology representing the traditional and highly reliable approach.

In through-hole mounting, component leads are inserted into drilled holes on a printed circuit board (PCB) and soldered in place. Typical through-hole packages include SIP/ZIP, DIP, and PGA. This article outlines the structural characteristics of DIP・PGA packages and introduces the test fixtures and contact probe technologies used to ensure reliable inspection and evaluation.

DIP・PGA — Cornerstones of Through-Hole Packaging When Through-Hole Packages Defined an Era

DIP and PGA packages were developed to accommodate higher pin counts and support increasingly sophisticated integrated circuits.

- DIP: Two parallel rows of pins extending from both sides of the package

- PGA: Pins arranged in a dense grid pattern on the bottom surface

These packages were widely adopted in electronic products throughout the 1980s and 1990s and remain familiar components in university laboratories and industrial test environments.

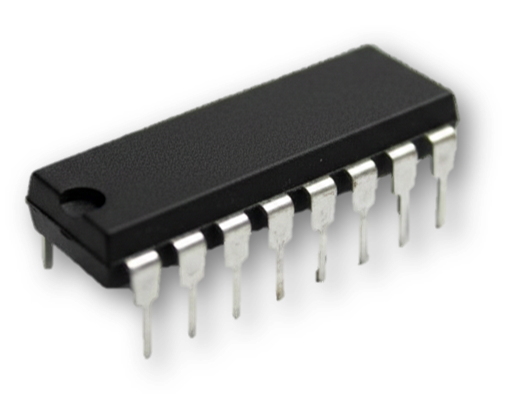

DIP (Dual In-line Package)

DIP is the most widely recognized through-hole package, featuring two straight rows of leads along the long edges of the package. Several variations exist to meet different application requirements:

| ・PDIP (Plastic DIP) | ・SDIP (Slim DIP) |

| ・CDIP (Ceramic DIP) | ・WDIP (Window DIP for EPROMs |

DIP packages remained popular for many years due to their ease of manual soldering, mechanical robustness, and compatibility with breadboards and sockets. Today, they are still commonly used in:

- Logic ICs (e.g., 74-series)

- Analog ICs (operational amplifiers)

- EPROMs and early-generation microcontrollers

Their continued use spans education, industrial equipment, and maintenance-oriented systems.

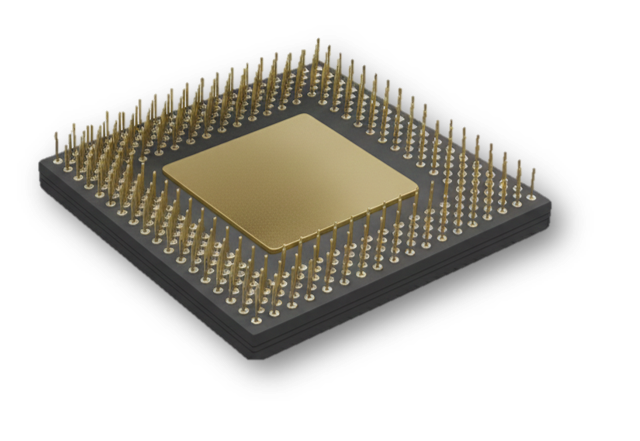

PGA (Pin Grid Array)

High Pin Counts with Grid-Style Precision, PGA packages place a large number of pins in a grid array on the underside, enabling significantly higher pin counts than DIP. This structure made PGA ideal for high-performance devices such as CPUs.

Notable applications include processors from Intel (Socket 7, Socket 370) and AMD (K6, Athlon).

Key characteristics:

- Support for very high pin counts

- Excellent electrical performance

- Keying pins to prevent incorrect insertion

While many PGA applications have transitioned to BGA (Ball Grid Array), ceramic PGA packages are still used in high-reliability servers, industrial systems, and mission-critical equipment.

Technical pros and cons of DIP・PGA

| Advantages | Disadvantages |

|---|---|

| Easy repair and replacement | Low mounting density; requires larger PCB area |

| Compatible with sockets for repeated insertion and removal | Not suitable for high-speed or high-frequency signal transmission |

| Supports high pin counts (especially PGA) | Large package size, limiting use in compact or mobile devices |

Fixtures required in inspection and test processes

As pin counts increase, stable and reliable electrical contact becomes critical during inspection and testing. Typical fixtures and probing solutions include:

- Probe fixtures for short/open testing

- Evaluation boards with high-durability sockets

- Probe blocks for simultaneous multi-point contact

- Spring probes to minimize contact resistance

- Integrated socket-type fixtures for automated handling

Seiken’s Solutions for Through-Hole Package Testing

| Challenge | Example solutions from Seiken *Click on each solution to learn more. |

|---|---|

| Fast manual testing of DIP | Socket + spring-probe fixtures |

| Stable contact for high-pin-count PGA | Pin blocks / Bias probes |

| Evaluation under high-temperature conditions | Heat-resistant probe solutions |

Because PGA grid pins are highly sensitive to deformation, precise probe load balancing is essential to maintain repeatable and reliable test results.

Despite the rise of surface-mount technology, DIP・PGA packages continue to play important roles in education, industrial electronics, and high-reliability applications. As pin counts increase, challenges such as unstable contact, pin deformation, and fixture mismatch become more prominent.

If you are experiencing testing issues or wish to optimize your inspection environment, Seiken offers tailored fixture and probe solutions designed for your specific requirements.

Please feel free to contact us—we are committed to supporting accurate, efficient, and reliable semiconductor testing.